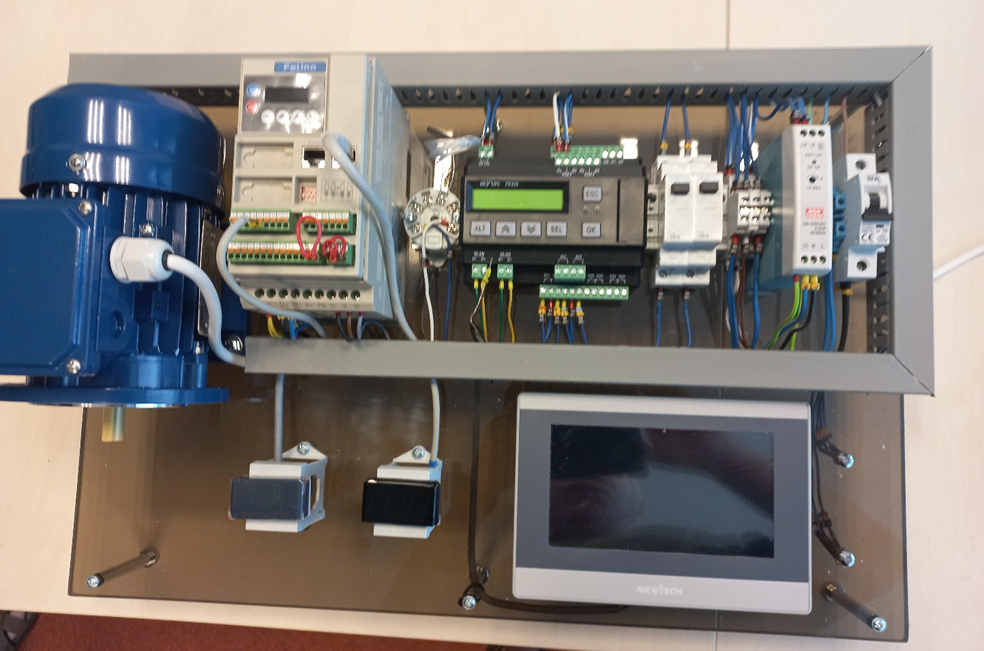

Over 90% of automation in one education station

Functionality implemented on the teaching station:

- PLC programming: FBD, ST,

- HMI programming,

- Establishing HMI-PLC communication: Modbus RTU,

- STO inverter programming,

- Establishing inverter-PLC communication: Modbus RTU, ( e.g frequency setting and starting the inverter, Modbus RTU ),

- ITP11 display programming ( 2-wire 4~20 mA ),

- SMI2 display programming ( Modbus RTU ),

- Establishing SMI2-PLC communication: Modbus RTU,

- NPT3 temperature transmitter programming,

- Reading temperature measured by a Pt100 sensor via NPT3 transmitter,

- Controlling 3-phase cage motor 3 x 230 V AC,

- Monitoring states of pushbuttons by the PR200 controller,

- Toggling LED diodes by the PR200 controller,

- Displaying chosen inverter analog value on the ITP11 display,

- Establishing HMI-SCADA communication ( SCADA application installed on a PC, Modbus TCP/IP ),

- Free programming/configuration software,

- School/university receives source code for all programs and lists of non-default parameters used,

- Powered with 230 V, 50 Hz, max 0,5 A.

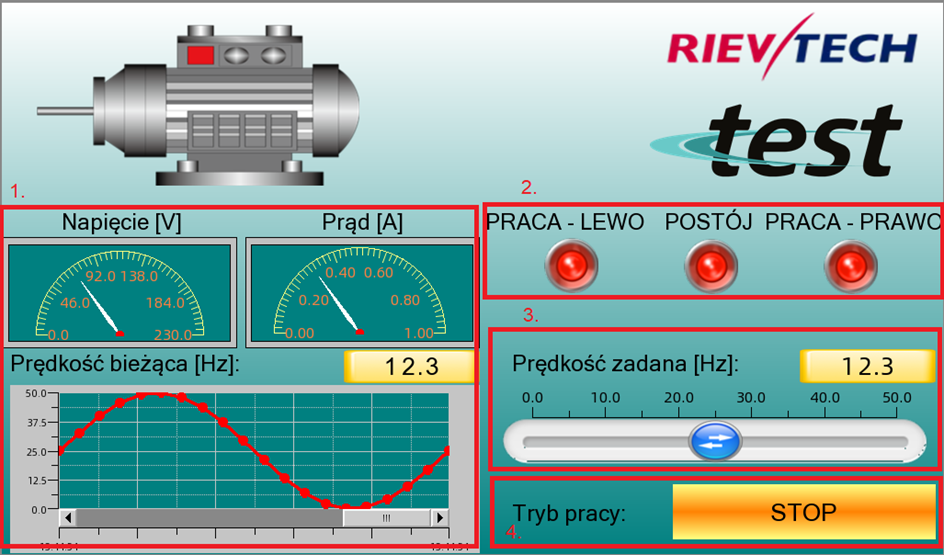

Functionality implemented on the HMI:

- Displaying running frequency, voltage and output current,

- Displaying inverter operation direction,

- Setting inverter frequency,

- Setting inverter operation mode.